How Predictive Maintenance Can Improve Plant Performance and Profitability

Predictive maintenance is a type of maintenance strategy that uses data analytics, machine learning, and other advanced technologies to monitor the condition of industrial equipment and anticipate when maintenance is required. By analyzing equipment data and performance metrics, predictive maintenance helps plant managers identify potential equipment failures before they occur, allowing them to schedule maintenance proactively and avoid unplanned downtime.

Predictive maintenance is essential for industrial plants as it can help reduce maintenance costs, improve equipment uptime, extend equipment lifespan, improve safety, increase productivity, and enhance decision-making.

Keep reading to find out more about:

- Understanding Predictive Maintenance

- Benefits of Predictive Maintenance

- Importance of continuous improvement and optimization

- Examples of successful predictive maintenance programs

Understanding Predictive Maintenance

Predictive maintenance is a maintenance approach that uses data analytics and machine learning to predict when equipment maintenance is required. Algorithms can identify patterns and trends that indicate likely equipment failures by analyzing sensor data, equipment performance, and other sources. This allows reliability and maintenance managers to schedule maintenance proactively, reducing downtime and maintenance costs.

Data analytics and IoT are essential components of predictive maintenance. IoT sensors collect data from equipment, which is then analyzed using data analytics tools. Data analytics algorithms use machine learning techniques to identify patterns and trends in the data that indicate potential equipment failures. By using this technology, plant managers can get real-time insights into equipment performance.

A predictive maintenance program typically consists of the following components:

Data collection: Data collection is the first step in a predictive maintenance program. Data is collected from equipment sensors and other sources and then used to build predictive models.

Data analysis: Data analysis uses analytics tools to identify patterns and trends that indicate potential equipment failures.

Predictive modeling: Predictive modeling is the process of building predictive models to anticipate when equipment maintenance is required.

Condition monitoring: Condition monitoring is the process of monitoring equipment performance in real-time. IoT sensors collect equipment performance data, which is then analyzed in real-time.

Maintenance scheduling: Maintenance scheduling is the process of scheduling maintenance activities based on the results of predictive modeling and condition monitoring.

Reporting and analytics: Reporting and analytics are regularly used to track the performance of the predictive maintenance program.

By implementing these components, plant managers can build an effective predictive maintenance program that optimizes maintenance schedules, reduces downtime, and improves equipment performance.

Learn more about Overcoming Common Challenges in Implementing Predictive Maintenance Programs

Benefits of Predictive Maintenance for Plant Operations

Increased equipment uptime

One of the primary benefits of predictive maintenance is increased equipment uptime. This helps to keep production lines running smoothly and avoids the costs associated with downtime, such as lost production, missed deadlines, and customer dissatisfaction.

Reduced maintenance costs

Predictive maintenance can also reduce maintenance costs. Predictive maintenance can also optimize maintenance schedules, reducing the frequency of maintenance activities and minimizing the need for reactive maintenance.

Improved safety

Predictive maintenance can improve safety by identifying potential safety hazards before they become serious problems. For example, sensors can detect equipment malfunctions that could lead to accidents, and maintenance can be scheduled to address these issues before they cause harm to employees or equipment.

Extended equipment lifespan

Proactive maintenance can extend the lifespan of the equipment. By performing regular maintenance activities and addressing potential issues before they become serious problems, the equipment can operate at peak performance for extended periods. This can reduce the need for costly equipment replacements and improve the return on investment for equipment.

Increased productivity

Predictive maintenance can also increase productivity by reducing unplanned downtime and minimizing equipment malfunctions. This allows production lines to operate more efficiently, increasing output and reducing waste. Predictive maintenance can also optimize maintenance schedules, reducing the frequency of maintenance activities and allowing production to run uninterrupted for more extended periods.

Improved decision-making

Finally, predictive maintenance can improve decision-making by providing plant managers with real-time equipment performance data. This data can identify trends and patterns that indicate potential issues, allowing managers to make data-driven decisions about maintenance activities and equipment replacements. Predictive maintenance can also help identify areas for improvement, enabling plant managers to boost the efficiency and effectiveness of their maintenance programs.

Learn more about How to Get Started with a Predictive Maintenance Program

The Importance of Optimizing Your Predictive Maintenance Program

Continuous improvement and optimization are critical to the success of a predictive maintenance program. By evaluating and refining the program, companies can improve the accuracy of their predictions.

Some best practices for continuous improvement and optimization include:

- Regularly reviewing and updating predictive models to ensure they remain accurate and relevant.

- Analyzing data to identify trends and patterns that can be used to improve the predictive maintenance program.

- Collaborating with equipment manufacturers and vendors can help organizations stay current on new technologies and best practices.

- Providing regular training for the maintenance team can help them stay up-to-date on the latest tools, technologies, and best practices for predictive maintenance.

Examples of Successful Predictive Maintenance Programs

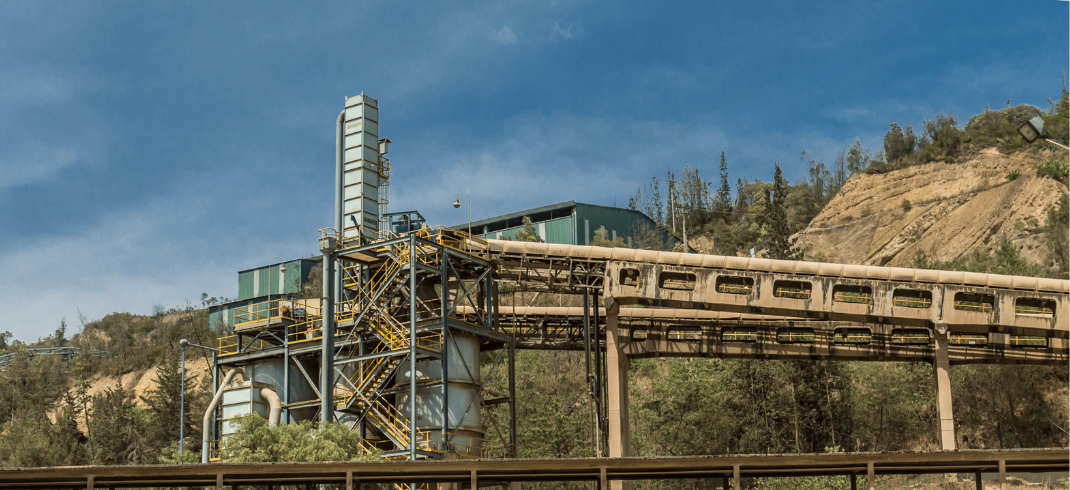

Case Study: Wireless Vibration Monitoring in Cement Industry

With a strong return on investment of 20x after two months, a cement factory in Europe managed to save more than 500.000,00 Euros by using DALOG's wireless vibration monitoring system.

At the start of the project, DALOG's team of technicians assessed the machines' health belonging to a cement factory in Italy and discovered the following:

✔ Three assets were in healthy condition, with no action required.

✖ Ten assets indicated an ongoing machine anomaly that must be followed up on but is not critical.

✖ Four assets indicated an alert or dangerous condition that must be closely followed, and maintenance should start planning repair works.

What did we do?

- We mounted wireless vibration sensors radially at the kiln bearings and gateways, connecting sensors directly to the DALOG cloud via a cellular network.

- Total number of Machines Monitored: 17

- Total Number of Wireless Vibration Sensors: 76

- Area Covered: Pyro Processing

- We set clear goals with the plant team to reduce asset indication and alert conditions.

- We set regular reliability meetings with the maintenance and reliability team and DALOG to follow up and improve machine availability.

The result: A strong return on investment of 20x after two months and more than 500.000 Euros saved by using DALOG's wireless vibration monitoring system.

In conclusion, predictive maintenance is a powerful tool that can help industrial plants to improve equipment uptime, reduce maintenance costs, improve safety, extend equipment lifespan, increase productivity, and improve decision-making. Organizations can proactively schedule maintenance, optimize production, and avoid unplanned downtime by using data analytics and IoT technologies to predict potential equipment failures.

Get started with predictive maintenance today. Learn more about DAWi - DALOG Wireless Solution.