How to Choose the Right Wireless Sensors [Infographic]

As industries continue to grow and evolve, the importance of predictive maintenance cannot be overstated. With unexpected downtime and equipment failures potentially costing businesses millions of dollars in lost revenue and repairs, the need for proactive monitoring has become paramount.

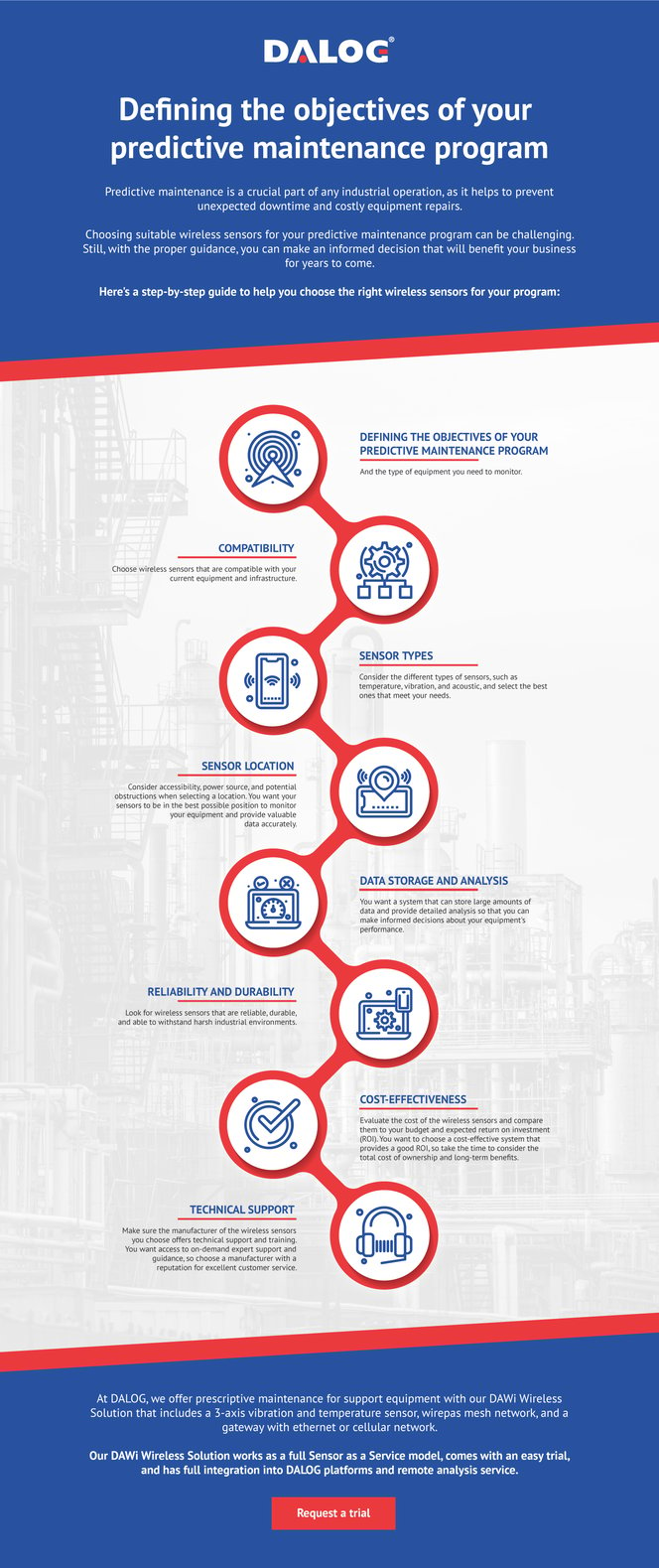

One of the critical components of a successful predictive maintenance program is the selection of the right wireless sensors. However, with many available options, choosing suitable sensors can be daunting.How wireless vibrations sensors work

Wireless vibration sensors are a vital tool in predictive maintenance, as they allow for the remote monitoring of mechanical equipment. These sensors are designed to detect and analyze machinery vibrations and transmit this data wirelessly to a monitoring system.

Wireless sensors are composed of a sensor element, a microprocessor, and a wireless transmitter. The sensor element detects and measures machinery vibrations while the microprocessor processes this data for analysis. Once the data is processed, the wireless transmitter sends the information wirelessly to a monitoring system. These sensors can provide critical real-time data on machinery performance, enabling proactive maintenance to prevent equipment failures before they occur.

Utilizing either WIFI or Bluetooth technology, wireless vibration sensors transmit data to a gateway for further analysis. Once at the gateway, the data can be integrated into the operator's local area network (LAN) or sent directly to the cloud through a cellular network connection. The next step is to process the data using web applications to create visualizations and generate valuable insights into machine conditions for predictive maintenance. These insights are critical to identifying potential equipment failures before they occur, enabling proactive maintenance and avoiding costly downtime.

To operate and transmit data, these sensors rely on batteries, which means they have a limited lifespan and must be recharged or replaced periodically. The primary factor determining a sensor's battery life is the type of batteries used and the temperature range at which the sensor operates. Typically, non-rechargeable batteries provide a longer lifespan than rechargeable batteries. By optimizing battery usage, your businesses can maximize the uptime of their equipment and ensure that sensors continue to operate optimally, delivering critical insights into machine conditions for predictive maintenance.

Wireless vibration sensors incorporate encryption technology to ensure secure data transmission and prevent unauthorized access. This measure effectively protects the transmitted data from hacking and other cyber attacks, providing businesses with the confidence that their critical data is secure. With the capability for remote machinery monitoring, these sensors help detect potential issues before they escalate into costly downtime. Additionally, their wireless functionality makes them a practical solution in remote locations or environments where establishing a wired connection is difficult or expensive.

Wireless vibration sensors play a crucial role in facilitating predictive maintenance and improving overall operational efficiency by providing businesses with a secure and efficient method for monitoring machinery.

How to choose the right wireless sensors for your program

Download and learn more about wireless vibration sensors from The Reliability Manager’s Plan: How to Choose the Most Cost-Effective Solution for Predictive Maintenance

Learn more about DAWi - DALOG Wireless Solution