5 Important Vibration Metrics to Monitor for Optimal Machine Performance

Unlocking the secrets to achieving optimal machine performance is a crucial objective if you're seeking to maximize productivity and minimize downtime.

In today's industrial landscape, condition monitoring and predictive maintenance are vital in achieving this goal. By closely monitoring the health and performance of machines, you can proactively identify potential issues and take timely corrective actions.

For example, over half of the manufacturing plants use predictive maintenance with analytical tools, with predictive analytics yielding a tenfold return on investment and resulting in savings of 30% to 40%. Now, these are some numbers you don't want to miss out on!

One essential component of effective machine monitoring is vibration analysis.

In this article, we will explore five essential vibration metrics that provide valuable insights into machine performance, identifying potential problems and ensuring optimal operational efficiency.

- Understanding Vibration Analysis

- The Five Important Vibration Metrics

- Implementing Effective Vibration Monitoring

1. Understanding Vibration Analysis

Vibration analysis is a powerful technique used to measure, analyze, and interpret vibrations in machinery. It involves collecting vibration data from various machine components and using specialized tools and methods to assess the vibration characteristics. It also provides valuable insights into potential issues, such as mechanical imbalances, misalignments, wear, or impending failures.

Early detection is critical because it allows you to take proactive maintenance measures, preventing costly breakdowns and unplanned downtime. By identifying and addressing problems in their early stages, you can minimize repair costs, extend the lifespan of equipment, and maintain uninterrupted production. For example, 91% of businesses reduce repair time and unplanned downtime after implementing predictive maintenance.

Condition monitoring and predictive maintenance play vital roles in optimizing machine performance. You can establish baseline values for various machine components by continuously monitoring vibrations and tracking deviations from normal behavior. According to a study by Deloitte, predictive maintenance increases equipment uptime by 10 to 20% while reducing overall maintenance costs by 5 to 10% and maintenance planning time by 20 to 50%.

Learn more on How to Get Started With a Predictive Maintenance Program

This proactive approach enables you to anticipate and address potential issues before they escalate, ensuring optimal machine performance, reducing downtime, and maximizing productivity. On average, predictive maintenance increases productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%.

By integrating condition monitoring and predictive maintenance practices, you can achieve efficient operations, enhance equipment reliability, and optimize maintenance schedules.

2. The Five Important Vibration Metrics

Metric 1: Acceleration

Acceleration refers to the rate at which the velocity of a vibrating component changes over time. In simpler terms, it measures how quickly the component speeds up or slows down during vibration. By capturing acceleration measurements, you can gain insights into the dynamic forces exerted on the machine.

Acceleration data helps you understand the intensity of vibrations and the forces that components are subjected to. Excessive acceleration can signify mechanical issues, such as imbalances, misalignments, or loose parts. These conditions, if left unaddressed, can lead to premature wear and fatigue.

Monitoring acceleration levels is pivotal for identifying potential issues and ensuring optimal machine performance. You can track deviations from normal behavior by establishing baseline acceleration values for different components. Sudden acceleration increases can indicate faults or impending failures, allowing you to take proactive maintenance measures before significant damage occurs. By keeping a close eye on acceleration, you can prevent costly breakdowns, extend the lifespan of machinery, and maintain smooth operations.

What Are Wireless Vibration Sensors and How to Connect Them

Metric 2: Displacement

Displacement refers to the distance a vibrating component moves from its resting position during vibration. It measures the extent of the movement or shift experienced by the component.

Displacement measurements play a crucial role in assessing the severity of vibrations and evaluating potential damage. By quantifying the displacement, you can determine the movement's magnitude and understand its impact on the machine and its components. Higher displacement values often indicate more severe vibrations, leading to increased wear and stress on the machinery.

Establishing baseline displacement values for different machine components allows you to compare ongoing measurements with the normal range, making it easier to detect anomalies or deviations. Monitoring displacement over time helps identify changes that may indicate misalignments, loose components, or other mechanical issues. By addressing these problems promptly, you can prevent further damage and maintain the optimal functioning of the machine.

How Do Vibration Sensors Work and Why Do You Need Them

Metric 3: Velocity

Velocity is the rate of change of displacement over time. It measures how fast a vibrating component is moving during vibration.

Velocity measurements provide valuable information about the speed at which a component vibrates. By analyzing velocity data, you can assess the magnitude and intensity of the vibrations, helping you understand the dynamic behavior of the machine.Monitoring velocity levels is important for detecting potential faults and abnormal machine behavior. Deviations from standard velocity patterns can indicate underlying issues, such as misalignments, unbalanced loads, or bearing wear. By closely monitoring velocity, you can identify these problems early and take necessary corrective actions to prevent further damage or failures.

Velocity is closely related to the energy transmitted to machine components. Higher velocities imply greater energy levels, increasing stress, fatigue, and potential damage. By closely monitoring velocity measurements, you can effectively manage the energy distribution within the machinery and ensure optimal machine performance.

The Advantages of Wireless Sensors in Predictive Maintenance Programs

Metric 4: Crest Factor

The crest factor is a measurement that compares a vibration signal's peak amplitude (highest point) to its RMS (Root Mean Square) amplitude. It is calculated by dividing the peak amplitude by the RMS amplitude.

Crest factor analysis is valuable in identifying the presence of harmonics, bearing defects, or other anomalies within the vibration signal. A high crest factor indicates the presence of irregularities or sudden changes in the vibration pattern, which can signify potential problems or abnormalities in the machine.

Monitoring the crest factor is essential for the early detection of issues before they escalate. Regularly assessing the crest factor values can identify changes or deviations from the normal range. This proactive approach allows you to take prompt action and prevent further damage or failures, ultimately reducing downtime and maintenance costs.

Crest factor analysis helps in determining the severity and type of vibration. Higher crest factors may indicate higher amplitudes during specific vibration cycles, suggesting potentially severe vibrations. By analyzing the crest factor, you can gain insights into the characteristics of the vibration and distinguish between different types of vibrations, such as unbalance, misalignment, or bearing faults.

How to Choose the Right Wireless Sensors [Infographic]

Metric 5: Frequency

Frequency refers to the number of vibration cycles occurring within a specific unit of time. It represents the rate at which the vibration repeats itself.

Frequency analysis is critical in identifying the source of vibrations and pinpointing specific issues within the machinery. By analyzing the frequency content of vibration signals, you can determine the frequencies at which vibrations occur. This information helps identify the underlying causes, such as unbalance, misalignment, gear meshing problems, or bearing defects.

Analyzing the frequency is vital for detecting potential faults and abnormal machine behavior. Each type of fault or issue produces unique frequency patterns in the vibration signal. By studying the frequency, you can identify these patterns and correlate them with known fault frequencies or characteristic frequencies of machine components. This enables you to diagnose the specific problems affecting the machinery accurately.

Monitoring changes in frequency over time is critical for early fault detection and diagnosis. You can compare ongoing measurements and identify deviations or anomalies by establishing baseline frequency for regular machine operation. A sudden change in frequency content may indicate the development of a fault or the progression of an existing issue. Early detection through frequency analysis allows you to take prompt action, preventing further damage and reducing the risk of unexpected failures.

3. Implementing Effective Vibration Monitoring

Leveraging advanced condition monitoring tools and technologies is crucial to achieving accurate and reliable vibration analysis. These tools enable you to precisely capture and analyze vibration data and understand machine health.

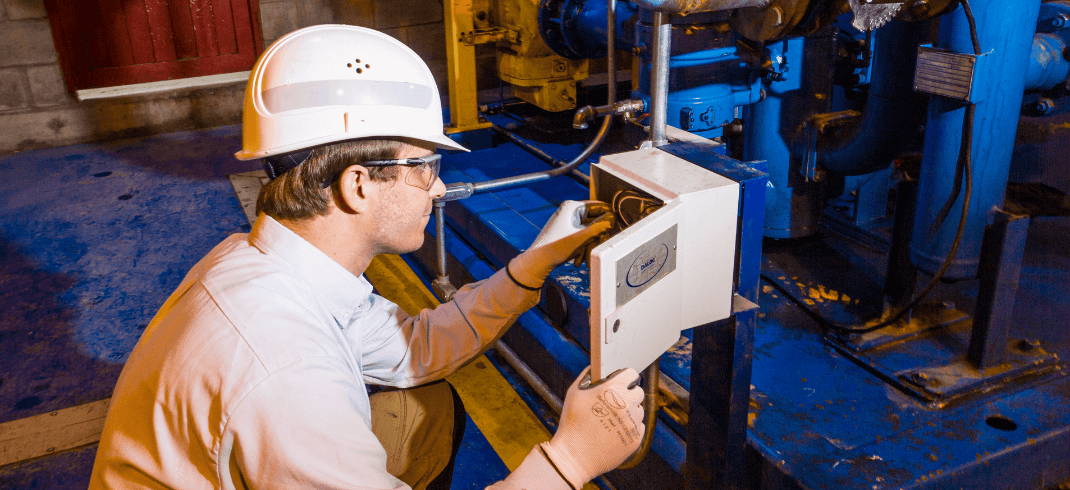

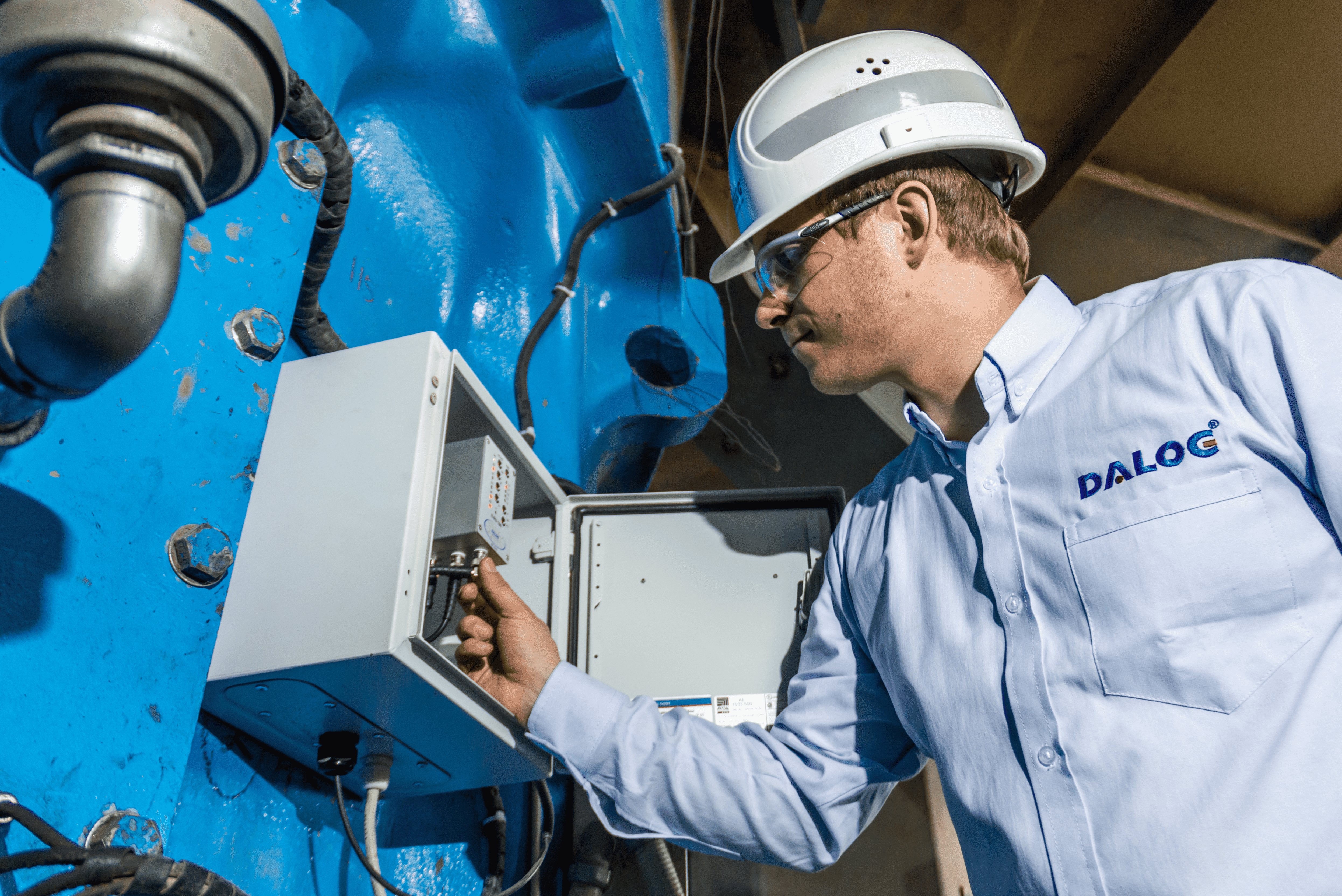

Data collection devices like accelerometers and vibration sensors are essential for capturing vibration data. These devices are strategically placed on the machine to measure and record vibrations accurately. They act as the eyes and ears of the monitoring system, providing valuable data for analysis.

Integrating vibration monitoring with predictive maintenance systems is a key strategy for proactive maintenance planning. You can identify trends, patterns, and potential failure modes by connecting vibration data with relevant operational and maintenance data. This integration enables you to develop predictive models, schedule maintenance tasks proactively, and optimize the utilization of resources.

Partnering with experts in vibration analysis and predictive maintenance can facilitate comprehensive machine health management. Take DALOG, for example - we have the expertise and knowledge to effectively monitor and analyze vibration data, provide accurate diagnoses, and recommend appropriate maintenance actions. Our guidance and support can significantly enhance your machinery's reliability, efficiency, and longevity.

If you're interested in an online reliability assessment, make sure to drop us a line.